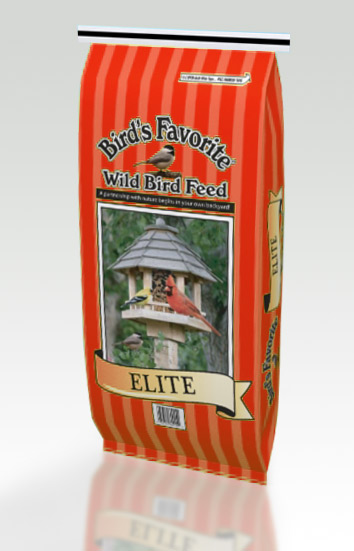

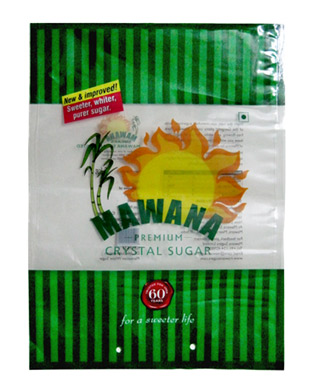

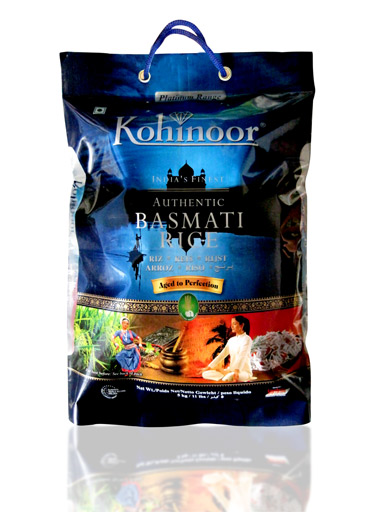

Flexible Packaging

We can supply very wide range of custom designed film, foil and paper based laminate structures, printed in up to 10 colors high quality process for primary packaging of products in any form i.e. (solid, powder or liquid), in sizes between 35 mm to 1000 mm and with holding capacity of 250 Grams to 25 Kgs. The customizing process optimizes design for achieving product protection, product filling productivity, brand image promotion and overall cost effectiveness. Specialized structures include those providing high barriers for tropical climate, high strength for transportation over long distances, high speeds on filling lines, Pre formed pouches, including stand-up and re-closeable are also options provided.

Packaging Structure:

- Reverse Printed PET Film + PE Film

- Reverse Printed BOPP Film + Met BOPP

- Reverse Printed Pet Film + Foil + PE Film

- Reverse Printed Pet Film + Metallised Pet + PE Film

- Polyethylene Films

Packaging Application:

- Food and Non-food Items

- Animal Feed and Minerals

- Confectionary and Biscuits

- Pharma, Soft Drink Concentrate

- Tea, Coffee,

- Agro chemicals, Seeds, Lube Oils

- Milk, Shopping bags & general purpose lamination substrate

Pouch Construction:

CENTER SEAL POUCHES |

|

|---|---|

SIDE GUSSET POUCHES |

|

FOUR/THREE SIDE SEAL POUCHES |

|

JUMBO ROLL |

|

STAND UP POUCH |

|

LAMINATES IN ROLL FORM

|

|

LAMINATES ROLL SPECIFICATION:

Printed on PET, BOPP, PVC, Cello, Poster Paper, Glassine Paper, Chromo Art Paper Laminated with various materials like CPP, EAA COEX, EVA COEX, SURLYN COEX, LDPE, LLDPE, LDPE COEX, LDHDLLDPE COEX, BOPP HS, PET HS, Aluminium foil, Metalised PET/BOPP

Specification:PVC, PVDC, Maplitho/poster/craft paper etc.